Direct Shear Test: Evaluating Soil Strength Under Applied Load

Direct Shear Test: Evaluating Soil Strength Under Applied Load

Direct Shear Test: Evaluating Soil Strength Under Applied Load

Introduction

The stability and durability of any structure start with understanding the strength of the soil it rests upon. One of the most reliable tests to assess soil strength is the Direct Shear Test. This crucial soil analysis method helps engineers determine how a soil sample will respond under applied loads, ensuring safe and efficient construction.

At Annoor Test Labs and Engineering Services Pvt. Ltd, we specialize in conducting soil testing, including the Direct Shear Test, to support civil engineers, students, and construction professionals in designing safer and more stable structures.

Purpose of the Test

The Direct Shear Test is conducted to determine the shear strength parameters of soil, which are critical for evaluating how soil responds under applied loads. The primary purpose of the test is to assess:

- Cohesion (C): The ability of soil particles to stick together.

- Angle of Internal Friction (φ): The resistance of soil particles to sliding over one another.

These parameters are crucial for:

- Foundation Design: Ensuring that foundations can support structural loads without failure.

- Slope Stability Analysis: Preventing landslides or soil collapse in embankments and hills.

- Retaining Wall Design: Ensuring walls can withstand lateral earth pressure.

- Pavement Construction: Evaluating subgrade strength to prevent cracking and deformation.

Importance in Engineering/Construction

The Direct Shear Test plays a critical role in engineering and construction by providing essential insights into soil behavior. Its significance includes:

- Foundation Design: Ensures that building foundations are stable and can safely bear structural loads, preventing settlement or failure.

- Slope Stability: Helps assess the risk of landslides or soil erosion, making it vital for designing embankments, dams, and natural slopes.

- Retaining Structures: Provides the necessary parameters to design retaining walls capable of withstanding lateral earth pressures.

- Pavement Engineering: Determines the shear strength of subgrades, ensuring durable and crack-free road construction.

- Earthworks and Excavations: Guides safe excavation and backfilling by evaluating soil’s resistance to shearing.

What is the Direct Shear Test?

Definition and Overview

The Direct Shear Test is a fundamental geotechnical testing method used to determine the shear strength of soil. Shear strength is a soil's ability to resist sliding or deformation when subjected to an applied load. This test helps measure the critical parameters of soil, such as cohesion and internal friction angle, which are essential for designing stable structures and foundations.

In the Direct Shear Test, a soil sample is placed in a specialized shear box that splits into two halves. A controlled vertical load (normal stress) is applied to the sample, and a horizontal force is gradually introduced to cause shearing along a predefined plane. By monitoring the applied forces and soil displacement, engineers can calculate the shear strength of the soil.

This straightforward and reliable test is widely used in construction projects to evaluate the suitability of soil for foundations, retaining walls, slopes, pavements, and other infrastructure. It provides valuable data to understand how soil will perform under real-world conditions, helping to ensure safety and structural integrity.

Types and Variations of the Direct Shear Test

The Direct Shear Test has several types and variations, each designed to address specific testing conditions, soil types, or project requirements. These variations are tailored to provide accurate and relevant data depending on the scenario. Below are the key types and variations:

1. Unconsolidated Undrained (UU) Direct Shear Test

- Used for saturated soil samples where no drainage is allowed during the test.

- Measures shear strength without considering the effects of consolidation or drainage.

- Suitable for short-term loading scenarios like rapid construction.

2. Consolidated Undrained (CU) Direct Shear Test

- The soil sample is consolidated under a given normal stress, but drainage is restricted during shearing.

- Helps assess the soil's strength under intermediate conditions.

- Useful for analyzing undrained strength in long-term projects where consolidation has already occurred.

3. Consolidated Drained (CD) Direct Shear Test

- The soil sample is consolidated, and drainage is allowed throughout the test.

- Measures long-term soil strength when the material has had time to consolidate and drain under load.

- Commonly used for analyzing slopes, retaining walls, and foundations under long-term loading.

4. Residual Shear Strength Test

- Conducted to determine the residual (post-peak) shear strength of soil.

- Useful for assessing soil behavior in landslide-prone areas or for remolded soils with a history of movement.

5. Multi-Stage Shear Test

- A single soil sample is subjected to multiple shearing stages under different normal stresses.

- Reduces the number of samples needed but may slightly compromise accuracy due to sample disturbance.

6. Large-Scale Direct Shear Test

- Designed for testing coarse-grained soils, rock aggregates, or geosynthetic materials.

- Useful in projects involving embankments, large foundations, or retaining structures.

These types and variations provide engineers with the flexibility to simulate different field conditions and analyze soil behavior comprehensively, ensuring safe and effective design solutions for diverse construction challenges.

Why is the Direct Shear Test Important?

The Direct Shear Test is a cornerstone of soil mechanics and geotechnical engineering, as it provides critical information about soil strength, a key factor in the design and stability of structures. Here’s why this test is so important:

1. Evaluation of Shear Strength

- Shear strength is one of the most crucial properties of soil, determining its ability to resist sliding or failure under applied loads.

- The Direct Shear Test directly measures the soil's response to shear forces, providing vital data for design and construction.

2. Foundation Design

- For structures such as buildings, bridges, and dams, soil shear strength plays a pivotal role in ensuring the stability of foundations.

- Understanding shear strength helps engineers design foundations that prevent settlement, tilting, or failure.

3. Slope Stability Analysis

- The test helps in evaluating soil stability for slopes and embankments.

- This is critical for projects involving highways, railways, and earth dams, where slope failures could have catastrophic consequences.

4. Earth Retaining Structures

- Retaining walls, sheet piles, and other support structures rely on accurate shear strength values to resist lateral earth pressures effectively.

- The test aids in ensuring these structures remain safe and functional over time.

5. Pavement Design

- In road and highway projects, the Direct Shear Test helps determine the strength of subgrade and base materials.

- Ensures the pavement structure can withstand traffic loads without excessive deformation.

6. Tailored Testing for Different Conditions

- The test can simulate various drainage conditions (drained, undrained, or consolidated), mimicking real-world scenarios for specific project needs.

- This flexibility makes it suitable for diverse construction applications.

7. Preventing Soil Failures

- By identifying potential weak points in soil, the test allows engineers to implement corrective measures, such as soil stabilization or selecting alternative foundation designs.

- Reduces the risk of construction delays and costly structural failures.

8. Economic and Sustainable Design

- Accurate shear strength data helps optimize material use, leading to more cost-effective and environmentally sustainable designs.

By offering precise insights into soil behavior, the Direct Shear Test ensures the safety, stability, and longevity of engineering projects, making it an indispensable tool in construction and geotechnical engineering.

Key Benefits and Applications of the Direct Shear Test

The Direct Shear Test is widely used in geotechnical and civil engineering due to its practical benefits and diverse applications. Below are the key advantages and the primary areas where this test is applied:

Key Benefits

- Simple and Cost-Effective

- The test setup and execution are relatively straightforward, making it economical for routine soil strength assessments.

- It requires less specialized equipment compared to other advanced soil testing methods.

- Direct Measurement of Shear Strength

- Provides accurate and direct measurements of the soil’s resistance to shear forces, a critical property in structural stability.

- Customizable Test Conditions

- Can be performed under drained, undrained, or consolidated conditions to simulate specific site scenarios.

- This flexibility allows engineers to evaluate soil behavior under real-world construction loads.

- Supports Foundation and Structural Safety

- Helps in designing stable foundations that minimize settlement and prevent structural failures.

- Ensures the longevity and safety of structures like buildings, bridges, and dams.

- Enhances Slope Stability

- Determines the shear strength of soil in slopes and embankments to prevent landslides and slope failures.

- Improves Pavement Performance

- Plays a significant role in analyzing subgrade and base layer materials for road construction, ensuring durability under heavy traffic loads.

- Optimized Material Use

- By providing precise soil strength data, the test allows engineers to optimize material use, reducing costs while maintaining safety and performance.

- Risk Mitigation

- Identifies potential soil failures in advance, enabling preventive measures such as soil stabilization or alternative designs.

Applications

- Foundation Design

- Used to evaluate the shear strength of soil for designing safe and stable foundations for buildings, bridges, and towers.

- Slope and Embankment Stability

- Aids in analyzing natural slopes, embankments, and man-made cuttings for projects such as highways, railways, and earth dams.

- Retaining Structures

- Provides essential data for designing retaining walls, sheet piles, and other earth-support systems to resist lateral forces effectively.

- Pavement Design

- Helps in selecting appropriate subgrade and base materials to ensure long-lasting roads and highways.

- Dams and Reservoirs

- Evaluates the stability of soil layers for the construction of earthen dams and reservoirs.

- Earthquake and Seismic Design

- Determines soil shear strength for designing earthquake-resistant structures and mitigating liquefaction risks.

- Soil Stabilization Projects

- Provides data for improving weak soils using techniques such as chemical stabilization or reinforcement.

- Geotechnical Site Assessments

- Used in pre-construction soil investigations to assess the feasibility and safety of engineering projects.

By offering reliable and versatile insights, the Direct Shear Test ensures the success and stability of various construction projects, from foundational works to large-scale infrastructure developments. It’s an invaluable tool for civil engineers and geotechnical professionals alike.

Comparison with Other Testing Methods

|

Test |

Purpose |

Advantages |

Disadvantages |

|

Disadvantages |

Shear strength under direct load |

Simple, cost-effective, quick results |

May not replicate all field conditions |

|

Triaxial Test |

Comprehensive stress analysis |

Precise and versatile |

Expensive and time-consuming |

|

Unconfined Compression Test |

Compressive strength of cohesive soils |

Easy to perform, requires no confining pressure |

Limited to cohesive soils |

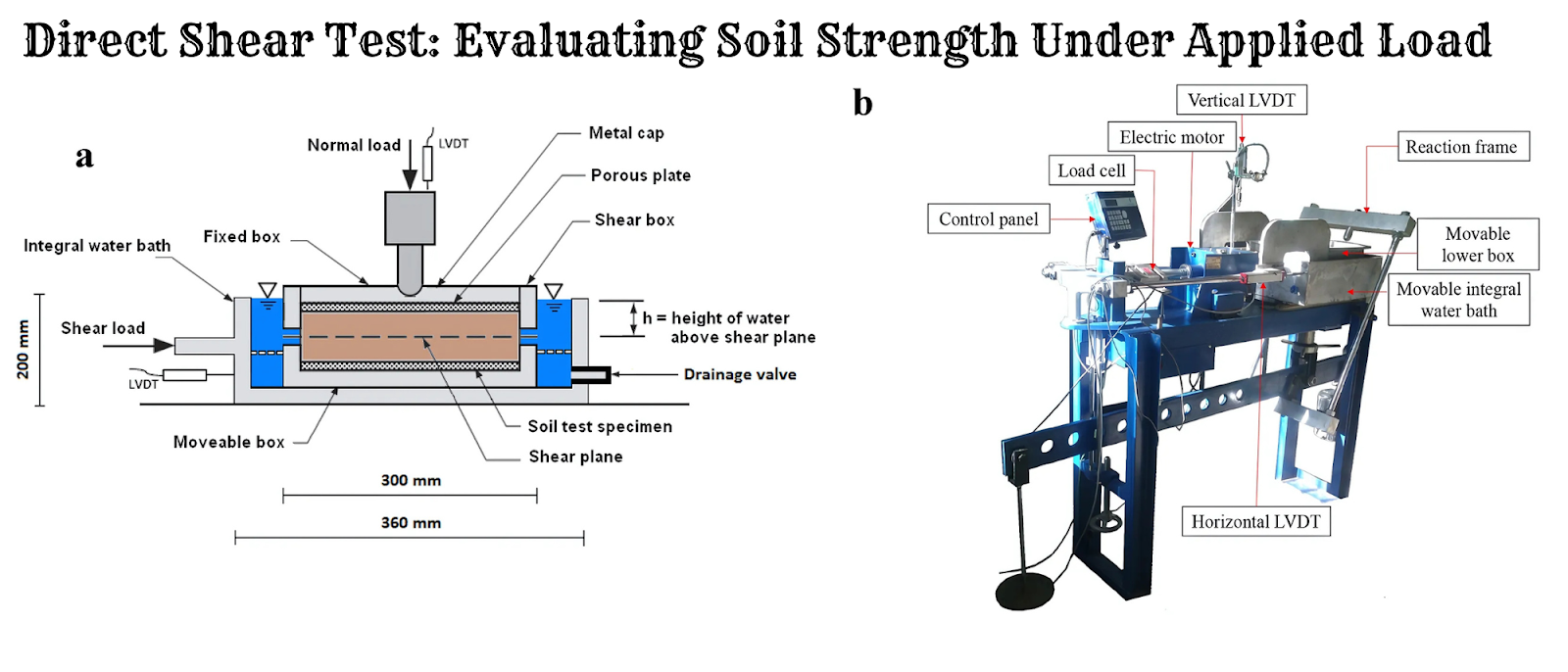

Equipment and Setup for the Direct Shear Test

The Direct Shear Test requires specialized equipment to determine the shear strength of soil under controlled conditions. Proper preparation and setup are critical to ensure accurate results.

Required Equipment and Tools

- Shear Box Apparatus

- A split, rectangular metal box that holds the soil sample.

- Composed of an upper and lower part to simulate shearing along a predefined plane.

- Loading Device

- Applies a vertical normal load to the soil sample during the test.

- Ensures the required stress conditions for the test.

- Horizontal Shearing Mechanism

- Moves the upper half of the shear box horizontally relative to the lower half to induce shear stress.

- Dial Gauges

- Measures horizontal displacement and vertical deformation.

- Helps in recording soil movements during the test.

- Proving Ring

- Measures the applied shear force with high accuracy.

- Sample Trimming Tools

- Includes tools like cutting rings, spatulas, and straight edges for preparing soil specimens to fit the shear box.

- Water Bath (Optional)

- Used to maintain specific moisture conditions for saturated soil samples.

- Weights

- Apply vertical stress (normal load) on the soil sample.

- Data Recording System

- May include a computerized data acquisition system for automated recording and analysis of test results.

Preparation and Site Setup

- Sample Collection

- Collect undisturbed soil samples using thin-walled tubes or trim soil specimens to fit the dimensions of the shear box.

- Alternatively, prepare remolded samples by compacting soil at a desired density and moisture content.

- Specimen Placement

- Place the soil specimen in the shear box, ensuring the top and bottom surfaces are level.

- If testing saturated soil, submerge the sample in water to maintain its natural state.

- Normal Stress Application

- Apply a predetermined vertical load to simulate field stress conditions.

- Calibration of Instruments

- Ensure dial gauges, proving ring, and loading mechanisms are properly calibrated for precise readings.

- Adjust Shear Box Settings

- Lock the upper and lower parts of the shear box together before starting the test.

By carefully assembling and calibrating the equipment and preparing the soil sample, you can ensure that the Direct Shear Test provides reliable and accurate results. This systematic setup forms the foundation of meaningful soil strength evaluations for construction and geotechnical projects.

Step-by-Step Procedure for the Direct Shear Test

The Direct Shear Test is performed to determine the shear strength of soil under controlled stress conditions. Below is a step-by-step guide:

Preparation and Initial Setup

- Sample Preparation

- Collect an undisturbed soil sample or prepare a remolded soil specimen at the desired density and moisture content.

- Trim the sample to fit the dimensions of the shear box (typically square or circular).

- Shear Box Setup

- Place the soil specimen into the shear box apparatus.

- Ensure the sample fits snugly between the upper and lower halves of the shear box.

- Porous Stones and Plates

- Position porous stones on both sides of the soil sample to allow drainage during testing.

- Insert loading plates on the top to distribute the vertical load evenly.

- Water Saturation (if applicable)

- If testing saturated soil, immerse the sample in water to replicate field saturation conditions.

- Calibration

- Calibrate the proving ring, dial gauges, and other instruments to ensure accurate measurements.

Test Execution Process

- Apply Normal Load

- Add weights to apply a specific vertical (normal) load.

- This simulates the stress experienced by the soil in field conditions.

- Shearing Mechanism Activation

- Unlock the upper half of the shear box.

- Begin applying horizontal force to the upper part at a constant strain rate.

- The lower half remains stationary, creating a shear plane along the sample.

- Measure Deformation

- Use dial gauges to record:

- Horizontal displacement (shear movement).

- Vertical displacement (change in soil volume).

- Use dial gauges to record:

- Monitor Shear Force

- Measure the applied shear force using the proving ring.

- Continue applying force until the soil fails (shear strength is exceeded).

Data Collection and Recording

- Data Recording

- Record:

- Horizontal displacement.

- Shear force readings.

- Vertical deformation.

- Note the peak shear force (shear strength).

- Record:

- Repeat for Different Normal Stresses

- Perform the test multiple times with different normal loads to establish the soil's shear strength envelope.

Post-Test Analysis

- Cleaning and Maintenance

- Remove the soil sample and clean the shear box and other equipment.

- Plot Results

- Plot shear stress vs. horizontal displacement to determine the peak shear stress.

- Plot the shear strength envelope by graphing shear stress against normal stress.

- Interpret Results

- Determine cohesion (c) and the angle of internal friction (φ) using the Mohr-Coulomb failure criterion:

- τ=c+σtan(ϕ)\tau = c + \sigma \tan(\phi)τ=c+σtan(ϕ), where:

- τ\tauτ = Shear stress.

- σ\sigmaσ = Normal stress.

- τ=c+σtan(ϕ)\tau = c + \sigma \tan(\phi)τ=c+σtan(ϕ), where:

- Determine cohesion (c) and the angle of internal friction (φ) using the Mohr-Coulomb failure criterion:

By following this procedure, the Direct Shear Test provides valuable data on soil strength, crucial for designing stable foundations, retaining walls, and other geotechnical structures.

Analysis and Interpretation of Results for the Direct Shear Test

The Direct Shear Test provides critical data to evaluate soil shear strength parameters, including cohesion (ccc) and the angle of internal friction (ϕ\phiϕ). Below is a detailed guide for analyzing and interpreting the results:

1. Data Collected During the Test

- Horizontal displacement (shear strain).

- Shear force applied.

- Normal load applied.

- Vertical displacement (change in soil volume).

2. Calculate Shear Stress

Shear stress (τ\tauτ) is calculated at each increment of horizontal displacement:

τ=FA\tau = \frac{F}{A}τ=AF

Where:

- FFF = Shear force.

- AAA = Cross-sectional area of the soil sample.

3. Plot Shear Stress vs. Horizontal Displacement

- Plot the shear stress on the y-axis and horizontal displacement on the x-axis.

- Identify key points:

- Peak shear stress: Represents the maximum shear resistance of the soil.

- Residual shear stress: Represents the shear resistance after large deformations.

4. Determine Shear Strength Parameters

Using the results from multiple tests at different normal stresses:

- Plot the shear stress vs. normal stress on a graph.

- Fit a straight line (failure envelope) to the data points.

The failure envelope equation is:

τ=c+σtan(ϕ)\tau = c + \sigma \tan(\phi)τ=c+σtan(ϕ)

Where:

- τ\tauτ = Shear stress.

- ccc = Cohesion.

- σ\sigmaσ = Normal stress.

- ϕ\phiϕ = Angle of internal friction.

5. Cohesion (ccc)

- The y-intercept of the failure envelope represents the soil's cohesion.

- Cohesion indicates the soil's strength due to interparticle bonding.

6. Angle of Internal Friction (ϕ\phiϕ)

- The slope of the failure envelope represents the angle of internal friction.

- This parameter indicates the soil’s resistance to shearing under normal stress.

7. Volume Change Analysis

- Use vertical displacement data to analyze soil volume changes during shearing:

- Dilation: Soil volume increases during shearing (common in dense sands).

- Compression: Soil volume decreases during shearing (common in loose sands and clays).

8. Interpreting Test Results

- High ccc and ϕ\phiϕ: Indicates strong, stable soil, suitable for heavy loads.

- Low ccc or ϕ\phiϕ: Suggests weak soil, requiring soil stabilization or special foundation designs.

- Significant volume changes: May necessitate consideration of settlement in design.

Practical Use

- Apply the obtained parameters (ccc and ϕ\phiϕ) in geotechnical designs such as retaining walls, slope stability analysis, and foundation design.

- Results help engineers predict soil behavior under real-world loading conditions.

By analyzing and interpreting these results, engineers can ensure safe and efficient construction practices while minimizing potential failures.

Common Data Patterns and What They Indicate in the Direct Shear Test

During a Direct Shear Test, the data collected provides insight into the soil's shear strength and its behavior under applied load. Analyzing the patterns in the data helps engineers make informed decisions regarding soil suitability for construction projects. Below are common data patterns and their interpretations:

1. Linear Shear Stress vs. Horizontal Displacement Pattern

- Pattern: A straight, linear increase in shear stress with horizontal displacement until peak stress is reached, followed by a gradual decline or leveling off (residual shear stress).

- Indication:

- This pattern is typical in cohesionless soils (e.g., sands).

- The initial linear increase represents the soil's resistance to shearing under normal stress.

- The decrease or leveling off after the peak stress indicates the soil's failure and formation of a residual strength, where the soil is still able to resist some shear but at a lower capacity.

2. Curved Shear Stress vs. Horizontal Displacement Pattern

- Pattern: Shear stress increases non-linearly with horizontal displacement, showing a curve instead of a straight line before reaching the peak stress.

- Indication:

- This pattern is more common in cohesive soils (e.g., clays).

- Cohesive soils generally exhibit significant strain before failure, which can lead to non-linear shear stress behavior.

- The curve indicates that the soil undergoes a process of deformation before reaching the peak shear stress, often due to plastic deformation of the soil particles.

3. No Significant Decrease After Peak Stress (No Residual Stress)

- Pattern: The shear stress does not significantly decrease after the peak value and remains constant or only slightly drops after failure.

- Indication:

- This pattern is indicative of strong, dense soils, where particle interlocking is high (e.g., gravels and dense sands).

- In such cases, the soil does not experience a significant loss of strength after the peak stress, which may indicate greater stability under sustained load.

4. Sharp Drop in Shear Stress After Peak

- Pattern: A sharp drop in shear stress after the peak stress is reached, followed by a small but steady residual strength.

- Indication:

- This is typical in loose or poorly compacted soils.

- A sharp drop after the peak indicates that the soil has reached its failure point rapidly, and after failure, it only retains a small amount of shear resistance.

- Loose sands or clays with high moisture content can exhibit this behavior, signaling the need for soil stabilization or additional foundation support.

5. Increasing Shear Stress with Increasing Normal Stress

- Pattern: A clear linear relationship between normal stress (σ\sigmaσ) and shear stress (τ\tauτ) during the test.

- Indication:

- A linear increase suggests that the soil is stable under increasing pressure, and the angle of internal friction (ϕ\phiϕ) can be directly derived from the slope of the line.

- This is typically seen in both sands and clays, with higher normal stresses resulting in higher shear resistance.

- Engineers use this relationship to understand the soil’s behavior under heavy load conditions and design accordingly for retaining structures, road foundations, and other critical applications.

6. Minor Horizontal Displacement with Low Shear Stress Increase

- Pattern: A minimal increase in shear stress, even with a significant horizontal displacement.

- Indication:

- This pattern is commonly observed in over-consolidated or stiff clays.

- The soil initially resists shear forces strongly but undergoes only minor additional displacement after the peak, indicating a higher level of cohesion and resistance to shearing under the applied load.

7. Significant Volume Change During Shearing (Compression or Dilation)

- Pattern: Large changes in vertical displacement (volume changes) are observed during the shear test.

- Indication:

- Compression: If the soil compresses significantly during the test (decreasing in volume), it indicates the soil is experiencing densification (common in loose sands and silty soils).

- Dilation: If the soil expands during shearing (increasing in volume), it indicates the soil is undergoing dilation (typically seen in dense sands).

- This behavior is important for understanding settlement characteristics and designing foundations, as soils that experience significant dilation can lead to issues like poor compaction or uneven settlement.

By recognizing these common data patterns and understanding their implications, engineers can better assess the suitability of the soil for various construction applications. The Direct Shear Test provides valuable insights into the shear strength of soils, helping in the design of safer and more stable structures.

Applications of the Direct Shear Test: Evaluating Soil Strength Under Applied Load

The Direct Shear Test is a vital soil testing method that helps assess the shear strength of soils, which is critical for the design and safety of various civil engineering projects. It plays a crucial role in providing valuable data for understanding how soil behaves under applied loads. Here are some key applications of the Direct Shear Test in different industries:

1. Foundation Design

- Application: The Direct Shear Test is widely used in foundation design to determine the shear strength parameters of soil, such as the cohesion (c) and angle of internal friction (ϕ). These parameters are critical for designing foundations that can withstand the loads from buildings, bridges, and other infrastructure.

- Use Case: For large buildings, the test helps to design deep foundations (e.g., piles) or shallow foundations (e.g., spread footings) to ensure that the soil beneath the structure has sufficient shear strength to support the imposed loads without excessive settlement or failure.

2. Pavement and Road Construction

- Application: The test is essential for evaluating the strength of subgrade soil and base materials used in the construction of roads and pavements. By understanding the shear strength, engineers can determine the suitability of the soil for supporting road construction and ensure proper load distribution.

- Use Case: In highway construction, the Direct Shear Test helps in designing the thickness of pavement layers to prevent failure due to inadequate soil strength, contributing to the longevity and safety of the roadway.

3. Slope Stability Analysis

- Application: The Direct Shear Test is instrumental in evaluating the shear strength of soil on slopes, which is essential for assessing slope stability. By analyzing the shear stress versus displacement curve, engineers can predict the soil's behavior under various loading conditions, identifying the risk of slope failure or landslides.

- Use Case: In hilly or mountainous regions, where natural slopes are common, the test helps in designing retaining walls, slope stabilization techniques, or drainage systems to prevent landslides or erosion.

4. Geotechnical Site Investigations

- Application: Geotechnical engineers often use the Direct Shear Test as part of site investigations to determine the shear strength properties of soil at different depths. This information is crucial for understanding soil conditions before construction begins.

- Use Case: During the initial stages of a construction project, especially in unknown or undeveloped areas, the Direct Shear Test provides vital information about the soil's stability and strength, allowing engineers to plan appropriate safety measures.

5. Dams and Reservoirs

- Application: The test is applied in the construction of dams and reservoirs to assess the shear strength of the soil in embankments and foundations. Understanding how soil will behave under load is essential for ensuring the integrity and safety of these large structures.

- Use Case: In the construction of a dam, the Direct Shear Test can be used to analyze the shear strength of the dam foundation soil, ensuring the dam's stability over time by preventing settlement or failure.

6. Retaining Wall and Soil Slope Design

- Application: In the design of retaining walls and soil slopes, the Direct Shear Test helps determine the shear strength parameters needed to design stable structures that can resist lateral pressures and prevent soil movement.

- Use Case: In areas where excavations or cuttings are required, the test helps assess the soil's ability to resist shear forces that could lead to instability or the failure of retaining walls.

7. Environmental Engineering and Waste Disposal Sites

- Application: The Direct Shear Test is used in environmental engineering for the design and assessment of waste disposal sites, such as landfills. It helps evaluate the shear strength of soil at the site to prevent soil collapse or failure, ensuring proper containment of waste materials.

- Use Case: For landfill projects, the test provides valuable data for designing stable embankments and barriers to prevent the leakage of hazardous materials, ensuring environmental safety.

8. Earthquake Engineering

- Application: In earthquake engineering, the shear strength of soil is an important factor in assessing how soil will behave during seismic events. The Direct Shear Test helps engineers understand the soil's resistance to shear forces during earthquakes, contributing to the design of structures that can withstand seismic activity.

- Use Case: In earthquake-prone regions, the test helps assess soil conditions for foundation design and provides insights into the risk of liquefaction, where loose saturated soils may lose their strength during an earthquake.

9. Subsurface Construction and Underground Structures

- Application: For constructing underground structures, such as tunnels and basements, the Direct Shear Test is used to evaluate the shear strength of the soil at various depths to ensure the safety and stability of the structure.

- Use Case: The test helps determine the soil's ability to support underground structures and contributes to the design of proper support systems, such as soil anchors and retaining walls, to avoid soil collapse.

10. Soil Stabilization Projects

- Application: The Direct Shear Test is used to evaluate the effectiveness of soil stabilization techniques, such as adding cement or other binding agents to increase the shear strength of weak soils. This helps engineers select the best stabilization methods for construction.

- Use Case: In areas with poor-quality soils, such as expansive clays, the test provides insights into how soil stabilization methods will improve the shear strength, ensuring that the soil can support construction activities.

The Direct Shear Test is a versatile and essential tool in geotechnical engineering, providing valuable data for the design of safe and stable foundations, pavements, slopes, and other construction elements. Whether you're planning a new construction project or involved in an ongoing one, understanding the shear strength of the soil beneath your structure is crucial for ensuring the longevity and safety of the project. At Annoor Test Labs and Engineering Services Pvt. Ltd, we offer comprehensive soil testing services to support your construction needs and help you make informed decisions for your projects.

Challenges and Limitations of the Direct Shear Test

While the Direct Shear Test is a valuable method for evaluating the shear strength of soils, there are several challenges and limitations associated with this testing method that can affect the accuracy and reliability of the results. These challenges must be considered when selecting the appropriate test for a given soil condition or construction project. Below are some of the key challenges and limitations:

1. Limited Simulation of Field Conditions

- Challenge: The Direct Shear Test simulates a simplified scenario of shear stress applied to the soil under controlled conditions. However, in real-world scenarios, soil is often subjected to complex, multi-axial stresses, which are not fully represented in the test.

- Impact: This simplification can sometimes result in shear strength values that are not entirely accurate when applied to certain field conditions. For example, in situations where soils experience both horizontal and vertical stresses (such as in foundations or embankments), the test may not fully capture the true shear strength.

2. Effect of Sample Disturbance

- Challenge: The accuracy of the test results depends on the integrity of the soil sample. During the process of sampling and handling, soil samples may become disturbed, altering their natural structure and moisture content.

- Impact: Disturbance can affect the shear strength properties of the sample, leading to unreliable results. This is especially a concern with cohesive soils (such as clays), which can be more sensitive to disturbance compared to granular soils (like sands).

3. Limited Applicability for Granular Soils

- Challenge: The Direct Shear Test may not provide accurate shear strength values for all types of soils, particularly highly granular soils or poorly graded soils.

- Impact: In granular soils, such as coarse sands or gravels, the test may not adequately capture the complex behavior of these soils under shear stress, particularly in cases where particle interlocking plays a major role in strength. In these cases, other testing methods, such as the triaxial test, may yield more reliable results.

4. Scale and Size Limitations

- Challenge: The Direct Shear Test is generally conducted on small soil samples, typically in a rectangular or square box. This may not represent the full variability of the soil at the project site, as soil conditions can vary across different layers and locations.

- Impact: A small-scale test may not fully capture the variation in shear strength across large construction sites, leading to results that may not fully reflect the site's conditions, especially in heterogeneous soils.

5. Difficulty in Determining Drainage Conditions

- Challenge: The Direct Shear Test can be performed under both drained and undrained conditions. However, accurately simulating the correct drainage conditions is challenging, especially for fine-grained soils such as clays.

- Impact: Incorrect assumptions about drainage conditions can lead to inaccurate shear strength parameters. For example, in undrained tests, the build-up of excess pore water pressure can affect the results, which is particularly important for soils subject to rapid loading, like during construction.

6. Time-Consuming for Large Number of Samples

- Challenge: For large-scale projects requiring multiple soil samples to be tested, the Direct Shear Test can be time-consuming. Each test requires careful preparation, execution, and data recording.

- Impact: When testing large numbers of samples, this can lead to delays in project timelines, especially if quick results are required for making critical decisions in the construction process.

7. Influence of Testing Equipment and Calibration

- Challenge: The accuracy of the test results depends significantly on the calibration and condition of the testing equipment. Inaccurate calibration or wear and tear of equipment can introduce errors in the test results.

- Impact: Incorrectly calibrated equipment can lead to incorrect measurements of shear stress and displacement, affecting the reliability of the results. Regular maintenance and calibration are essential to ensure accurate and consistent results.

8. Cost Considerations

- Challenge: The cost of conducting a Direct Shear Test, including the purchase of equipment and sample preparation, can be significant, especially for small-scale projects or when numerous tests are required.

- Impact: This can make the test less attractive for projects with limited budgets, especially in cases where alternative, less expensive testing methods can be used.

9. Not Suitable for All Soil Types

- Challenge: The Direct Shear Test is primarily suited for cohesive and granular soils but may not be ideal for certain special soil types such as expansive clays or organic soils.

- Impact: For soils that exhibit complex behavior, such as swelling or shrinkage (as with expansive clays), other tests like the Atterberg Limits test or triaxial tests may provide more accurate insights into their shear strength characteristics.

While the Direct Shear Test is an essential tool for evaluating soil strength under applied loads, it is not without its challenges and limitations. Understanding these challenges allows engineers to make informed decisions on whether the Direct Shear Test is the best option for their specific project. In cases where the test's limitations are a concern, alternative methods, such as the triaxial test or vane shear test, may be more suitable. Despite these limitations, the Direct Shear Test remains a widely used and effective method for many common geotechnical applications, providing valuable insights into soil strength for foundation design, slope stability, and other critical construction factors.

Best Practices for Direct Shear Test

To ensure that the Direct Shear Test yields reliable and accurate results, it is crucial to follow a set of best practices. These practices will minimize errors, improve the quality of the data, and ensure that the test results can be used effectively in construction and engineering applications. Below are some key best practices to follow when conducting the Direct Shear Test:

1. Proper Sample Handling

- Best Practice: Handle soil samples carefully to minimize disturbance. Soil samples, especially cohesive ones like clays, can lose their natural structure and strength properties if mishandled.

- Why it’s Important: Disturbing the soil sample can alter its shear strength properties, leading to inaccurate results. Always avoid compaction or drying out the sample before the test, and try to take samples at the right moisture content for the test.

2. Adequate Sample Preparation

- Best Practice: Prepare soil samples according to standard guidelines. For the Direct Shear Test, the sample should be placed in the shear box and carefully leveled to ensure uniform contact between the soil and the box walls.

- Why it’s Important: Uneven preparation of the sample can lead to inconsistencies during the test. Proper sample preparation ensures that the test conditions closely resemble real-world conditions, leading to more accurate results.

3. Consistent Test Conditions

- Best Practice: Ensure that the testing conditions, including moisture content, density, and compaction, are consistent with field conditions. For example, if the test is meant to simulate field conditions at a specific moisture content, do not allow the sample to dry out before testing.

- Why it’s Important: Consistency in test conditions ensures that the results accurately reflect the behavior of the soil under the same conditions it will experience in the field.

4. Correct Test Setup

- Best Practice: Calibrate all equipment before starting the test. This includes ensuring the shear box is aligned properly, the applied load is evenly distributed, and the displacement measuring device is accurate.

- Why it’s Important: Misalignment or inaccurate calibration of equipment can introduce errors into the test results. Ensuring correct setup minimizes the risk of unreliable data.

5. Choose Appropriate Shear Rate and Load Increment

- Best Practice: Select a suitable shear rate and load increment for the soil type being tested. For example, a slow shear rate may be more appropriate for cohesive soils like clays, while sands may require a faster rate.

- Why it’s Important: The shear rate affects how the soil responds to applied loads. Selecting an appropriate rate ensures that the shear strength behavior is accurately captured, and that pore pressure and drainage are adequately considered.

6. Perform the Test Under Both Drained and Undrained Conditions (If Applicable)

- Best Practice: For fine-grained soils, perform the test under both drained and undrained conditions, depending on the project's needs. This helps to evaluate the soil's response to loading both with and without allowing pore water pressure to dissipate.

- Why it’s Important: The behavior of cohesive soils, such as clays, differs significantly between drained and undrained conditions. Drained tests allow pore pressure to dissipate, while undrained tests do not, providing more insights into the soil’s true shear strength under different loading conditions.

7. Multiple Test Replicates

- Best Practice: Conduct multiple tests for different samples taken from different locations or depths at the same site. This helps identify variability in soil strength across the project area.

- Why it’s Important: Soil properties can vary across a site, and performing several tests ensures that the average shear strength is representative of the entire area. This also improves the reliability of the test results.

8. Proper Recording and Data Collection

- Best Practice: Accurately record all test parameters, including applied normal stress, shear stress, and displacement values, during the test. Use digital devices where possible to ensure precise data collection.

- Why it’s Important: Accurate data collection is essential for proper analysis and interpretation. Recording all the test parameters ensures that no critical information is overlooked during analysis.

9. Analysis of Results with Consideration of Field Conditions

- Best Practice: After completing the test, analyze the results in the context of the specific field conditions. Take into account factors like soil type, moisture content, and previous testing data to interpret the shear strength values.

- Why it’s Important: Soil behavior in the lab may differ from field behavior due to differences in loading conditions, soil stratigraphy, and environmental factors. A proper analysis ensures that the test results can be accurately applied to real-world conditions.

10. Use Proper Safety Precautions

- Best Practice: Always follow laboratory safety protocols when handling soil samples and operating shear testing equipment. This includes using personal protective equipment (PPE) and ensuring the test area is clear of obstacles.

- Why it’s Important: Safety precautions are critical to prevent accidents or injuries in the testing process. Handling equipment and materials correctly ensures a safe testing environment.

11. Regular Equipment Calibration

- Best Practice: Regularly calibrate testing equipment, including the shear box, loading system, and displacement measuring devices. This ensures the test's accuracy and minimizes errors due to equipment malfunctions.

- Why it’s Important: Over time, equipment can lose calibration, leading to inaccurate results. Regular maintenance and calibration ensure that the equipment provides precise and reliable data.

12. Maintain Proper Documentation

- Best Practice: Keep detailed records of each test, including sample information, testing conditions, observations, and test results. This documentation should be stored in a way that is easy to access for future reference.

- Why it’s Important: Proper documentation helps in tracking the progress of testing, maintaining quality control, and providing historical data for future projects or analysis.

By following these best practices, engineers and technicians can ensure that the Direct Shear Test provides reliable and accurate results that can be used for critical construction decisions. Proper preparation, consistent testing conditions, and careful data analysis are key to making the most of this valuable geotechnical test. These practices also help ensure that the results are applicable to real-world conditions, reducing risks in foundation design, slope stability, and other key engineering applications.

Conclusion

The Direct Shear Test is indispensable for understanding soil strength and ensuring safe construction. At Annoor Test Labs and Engineering Services Pvt. Ltd, we provide reliable testing services tailored to the needs of civil engineers, construction professionals, and students. With precise testing and expert guidance, we help ensure the success of your projects.

The Direct Shear Test is governed by various Indian Standards (IS Codes) to ensure the consistency, accuracy, and reliability of test procedures. The relevant IS Codes that apply to the Direct Shear Test for soil strength evaluation include:

1. IS 2720 (Part 13) – 1986: Methods of Test for Soils - Part 13: Direct Shear Test

This is the primary IS code for the Direct Shear Test in India. It provides detailed guidelines on:

- The apparatus required for conducting the test

- The procedure to follow

- The interpretation of test results

- Calibration and safety requirements

2. IS 2720 (Part 1) – 1983: Methods of Test for Soils - Part 1: Preparation of Soil Samples

While not specifically related to the shear test, IS 2720 Part 1 offers guidance on how soil samples should be collected, stored, and prepared before testing to ensure the results are accurate.

3. IS 2720 (Part 4) – 1985: Methods of Test for Soils - Part 4: Grain Size Analysis

Understanding the grain size distribution is important for interpreting shear strength, and IS 2720 Part 4 provides methods for conducting a grain size analysis of soil samples. The results of this test can aid in the interpretation of direct shear test results.

4. IS 2720 (Part 5) – 1985: Methods of Test for Soils - Part 5: Determination of Liquid Limit, Plastic Limit and Plasticity Index

Soil plasticity and consistency also play a role in its shear strength, and this code outlines procedures for determining the liquid limit, plastic limit, and plasticity index of soils.

5. IS 4434 – 1979: Method for Determination of Shear Strength of Soil by Direct Shear Test (using a Shear Box Apparatus)

This standard provides specifics on the apparatus and setup needed for conducting the Direct Shear Test and ensures that the test is carried out in a standardized and reproducible manner.

The Direct Shear Test is a crucial method for evaluating soil strength under applied load, and adherence to the relevant IS Codes ensures that the test is performed consistently and provides accurate, reliable data for engineering purposes.

Case Studies

- Slope Stability in a Highway Project

A highway embankment faced recurring landslides. The Direct Shear Test revealed low shear strength, prompting the use of geotextiles for stabilization, ensuring long-term safety. - Foundation Design for a Multi-Story Building

For a commercial complex, the test identified weak soil layers. Reinforcement with stone columns and a raft foundation prevented structural failures.

Read More